Image used courtesy of Encata

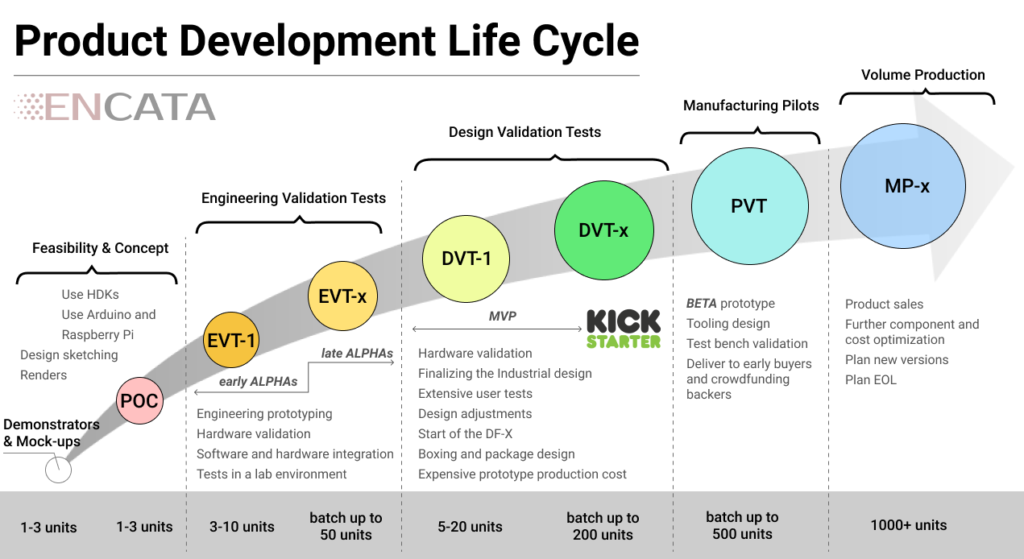

The New Product Introduction (NPI) process is a structured approach that transitions a technology product from concept to mass production. It consists of four key phases: Prototype (Proto), Engineering Validation Test (EVT), Design Validation Test (DVT), and Production Validation Test (PVT). Each phase plays a critical role in refining the product and ensuring readiness for market launch.

1. Prototype (Proto) Phase

The Proto phase is the earliest stage in the product lifecycle. Its main goal is to create basic models of the product to evaluate feasibility and functionality. This phase includes:

- Concept validation: Creating rudimentary prototypes, often using 3D printing, CNC machining, or other rapid prototyping techniques, to test core ideas and identify technical challenges.

- Iterative refinement: Rapid cycles of build, test, and revise to assess initial usability, functionality, and product-market fit.

- Stakeholder feedback: Gathering input from internal teams, potential customers, or partners to refine the product vision.

The Proto phase helps confirm that the product concept is both viable and aligned with user needs before moving into more advanced stages.

Example:

You’re making a new coffee mug. In the Proto phase, you use clay to shape a rough mug to test its size and handle placement. It’s not ready for use, but it shows how the design feels.

Key Activities:

- Build simple models to visualize the product.

- Check if the idea is practical.

2. Engineering Validation Test (EVT)

The EVT phase builds upon the Proto phase by focusing on validating the product’s engineering design and functionality. Key objectives include:

- Developing prototypes that integrate production-intent materials and technologies.

- Conducting in-depth tests to ensure the product performs as intended under various conditions.

- Resolving any technical challenges that may hinder performance or reliability.

EVT is where the product begins to take shape as a fully functional version, but it’s not yet ready for mass production.

Example:

You make a mug using the actual ceramic material to see if it holds hot coffee without cracking. You also test if the handle stays cool enough to touch.

Key Activities:

- Build functional versions using real materials.

- Test if it works and fix issues.

3. Design Validation Test (DVT)

In the DVT phase, the focus shifts from engineering to ensuring the product design is ready for large-scale manufacturing. Activities include:

- Using production-capable parts and tools to create test units.

- Validating consistency in quality and yield through rigorous testing.

- Refining manufacturing processes to ensure they meet scalability requirements.

This phase ensures that the product design can be manufactured at scale without compromising on quality or performance.

Example:

You make 20 mugs using the factory’s machines to see if each mug looks the same and works the same. If some handles are crooked, you adjust the production process.

Key Activities:

- Use factory tools to make small batches.

- Test if production is smooth and consistent.

4. Production Validation Test (PVT)

The final step, PVT, is the ultimate readiness check for mass production. During this phase:

- The production line is tested at full capacity to identify bottlenecks and defects.

- A limited quantity of units is produced and often sold to early customers to confirm manufacturing reliability.

- The supply chain, tooling, and processes are optimized to support mass production.

PVT ensures that the entire ecosystem—production, logistics, and quality control—is ready for the product’s market launch.

Example:

You produce 100 mugs in one day to confirm the factory can handle a large order. You also sell some to test if customers are happy with the product.

Key Activities:

- Run the factory at full speed.

- Test the whole process, from production to delivery.

By following these structured phases, businesses can confidently bring high-quality products to market, minimizing risks and maximizing success.